LUBRICACIÓN ESTRATÉGICA.

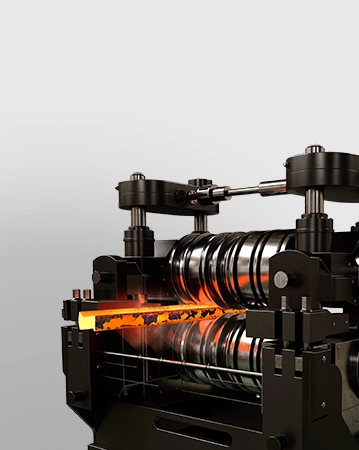

Haz tu lubricación industrial más inteligente

Reduce fallas y mejora tu productividad con lubricación estratégica. Atrévete a ser parte de la evolución industrial.

Conozca más sobre la lubricación industrial estratégica Descubra como